Pallet Dimensions

- Home

- Pallet Dimensions

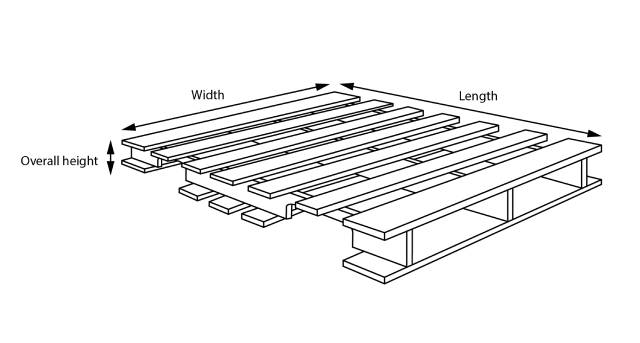

Standard pallet dimensions and sizes

The Consumer Brand Association (CBA—formerly known as the GMA) influences the consumer packaged goods industry around the globe.

Their standard pallet dimensions are 48″X40″—roughly 4’x3.33′ or 160 sq. feet if you’re looking for a quick conversion. Despite the group’s name change in 2019, pallets of this size are still commonly referred to as GMA pallets.

More than 30% of pallets produced in the U.S. each year are GMA pallets. The next most common pallet dimensions are 42” x 42” and 48” x 48” respectively.

- Standard pallet sizes

- 48" x 40"

- 42" x 42"

- 48" x 48"

Choosing the right pallet type for your shipment

There are several types of pallets, with names based on their construction. Below are the five most common pallets seen in shipping and a brief description of what separates them from one another.

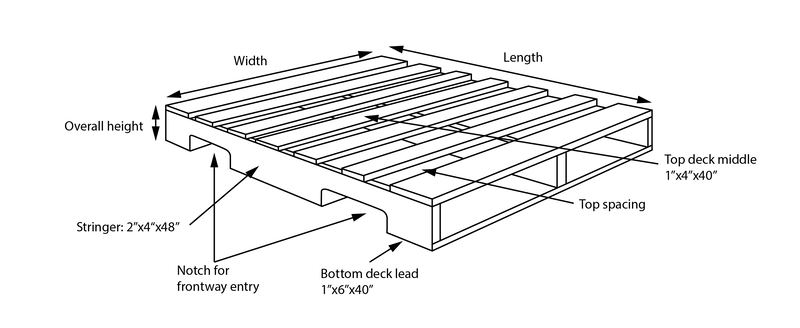

1. Stringer pallets

Stringer pallets are built with 2″X4″ wood, plastic, or metal stringers. These pallets use boards known as “stringers” that run between the top and bottom deck boards to add increased load support.

These pallets can come in either a “two-way” or “four-way” design. Two-way pallets allow for forklifts to enter from two sides and are sometimes referred to as “unnotched.” Four-way pallets allow forklifts to enter the pallet from any side.

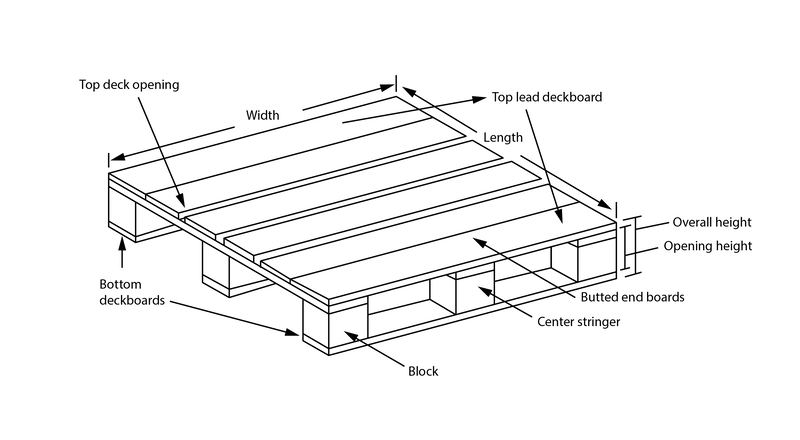

2. Block Pallets

Block pallets are typically sturdier, made with both parallel and perpendicular stringers. They are a four-way pallet that uses cylindrical posts to stabilize the top deck. These pallets can vary significantly. There are a variety of configurations that exist for block pallets. Models are available with or without top or bottom boards.

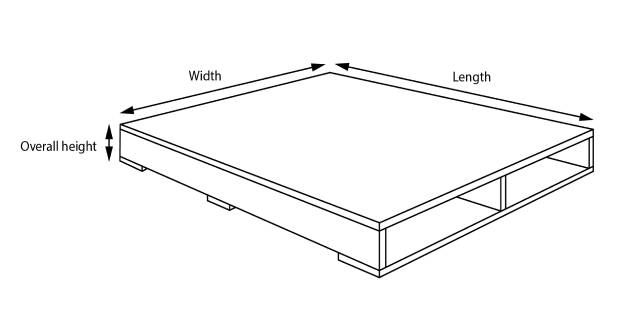

3. Solid Deck Pallet

The Solid Deck pallet offers a superior alternative to traditional pallets, particularly when it comes to handling heavier or uneven loads. Unlike standard pallet sizes with gaps between deck boards, the Solid Deck boasts a fully connected top surface, creating a seamless platform for optimal load stability. This unique design acts as a built-in preventative system, effectively distributing weight and minimizing the risk of shifting or toppling during transport or storage.

4. Double Face Pallet

As the name implies, double face pallets have decks on both the top and bottom of the pallet. The addition of a bottom deck strengthens the pallet and more evenly distributes the weight of the load.

These pallets come in both reversible and non-reversible models. Reversible models can hold a load on either side. To tell the difference between a reversible and non-reversible pallet, check the density of the board placement on each side. Non-reversible pallets should have one side that is sturdier than the other.

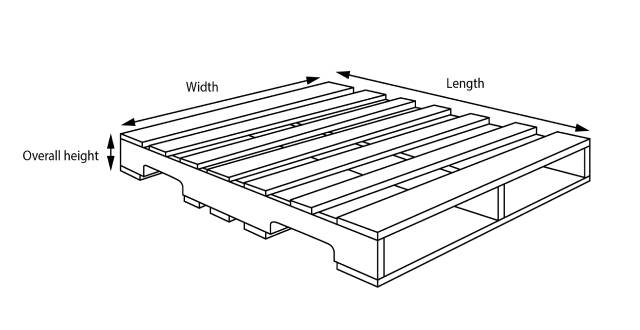

5. Double Wing Pallet

When looking at the pallet directly, double wing pallets have the appearance of “wings” because top and bottom deck boards extend beyond the stringers.

In addition to these common types, there are also specialized pallets designed for specific applications. Choosing the optimal pallet for a specific application depends on various factors such as load weight, load size, product type, and transportation needs.

Work with our dedicated Freightquote by C.H. Robinson experts to answer questions about pallet and equipment types.